How to Choose Brake Pads? OEM / Ceramic / Semi-Metallic – What’s the Difference? An Ultra-Detailed Buying Guide

Braking is the first line of defense for safety while driving, and brake pads, as the core component of the braking system, directly affect the stability of every stop. With numerous types of brake pads on the market, OEM, ceramic, and semi-metallic are the three main categories, often leaving car owners confused. Today, we provide an ultra-detailed buying guide covering performance, suitable scenarios, pros, and cons!

I. Analysis of Three Main Types of Brake Pads

1. OEM Brake Pads: The Certified "Worry-Free" Match

Core Composition: Formulated specifically by the vehicle manufacturer, typically a blend of semi-metallic, low-metallic, or organic materials. Formulas vary significantly between brands and models.

Key Advantages:

Perfect Compatibility: Designed to fully match the original brake rotors, providing linear pedal feel without issues like insufficient braking or abrupt stops. The braking process is smooth and predictable.

Warranty Support: Meets the manufacturer's quality standards. Some OEM pads come with a manufacturer's warranty, and any issues can be addressed directly through the dealership.

Broad Applicability: Suitable for basic braking needs in daily city commutes, highway driving, and occasional light mountain road use.

Drawbacks:

Higher Price: Typically 30%-50% more expensive than aftermarket parts of similar specifications, offering less value for money.

No Performance Highlights: Tuned conservatively to balance smoothness and durability, they may not satisfy drivers seeking aggressive braking performance.

Best For: Practical everyday drivers who prefer a hassle-free option, especially owners of luxury brands or electric vehicles.

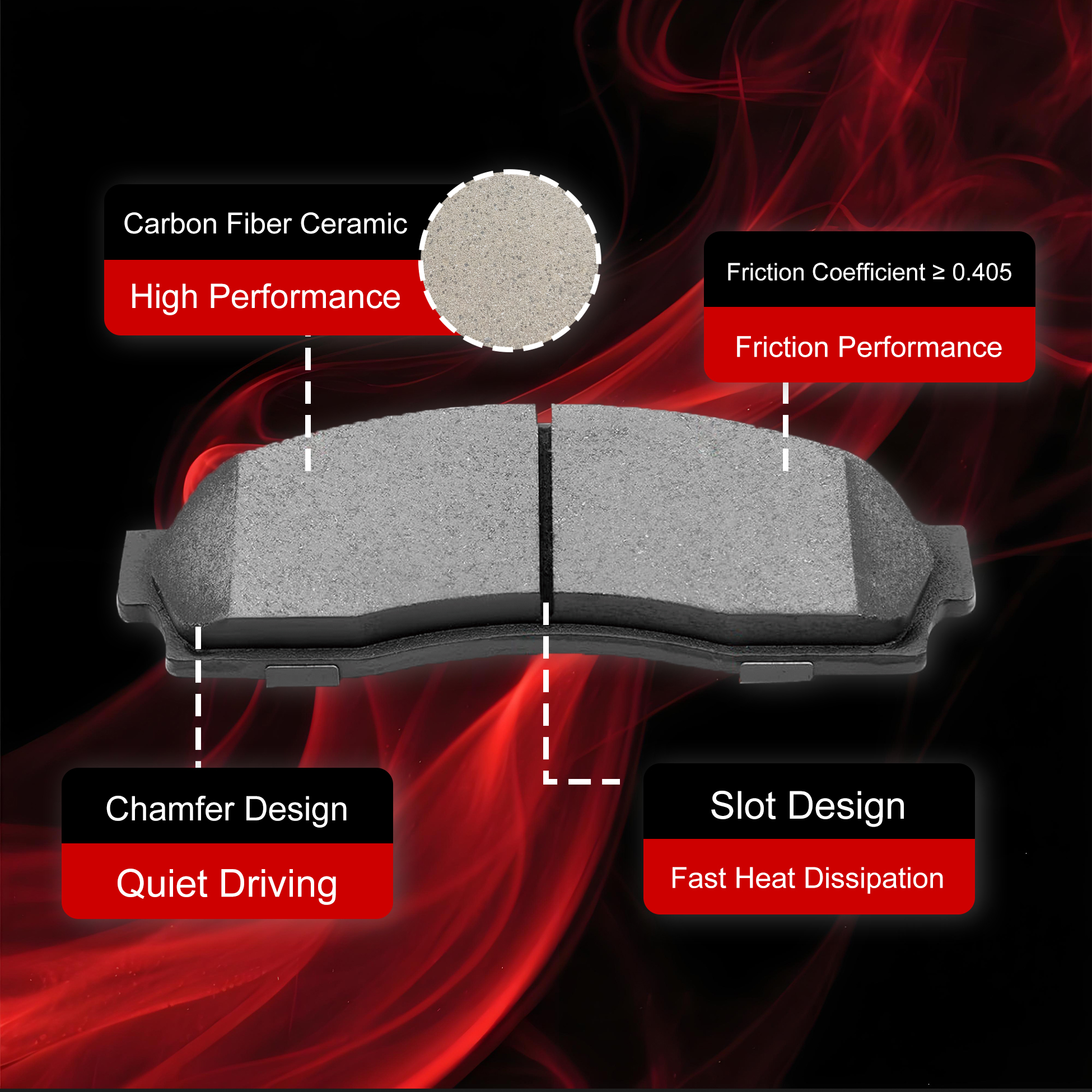

2. Ceramic Brake Pads: The Quiet & Clean "Comfort" Choice

Core Composition: Made primarily from ceramic fibers, mineral fibers, and resins, containing no metal. A popular eco-friendly option in recent years.

Key Advantages:

- Excellent Noise Reduction: Stable friction coefficient results in minimal noise during braking, almost eliminating harsh squealing.

- Low Dust & Easy Cleaning: Produce fine, non-adhesive dust that doesn't heavily soil wheels, reducing the need for frequent wheel cleaning.

- High-Temperature Resistance & Fade Resistance: Excellent heat dissipation helps maintain consistent braking power during continuous braking (e.g., mountain descents, highway emergency stops), effectively resisting "brake fade."

- Longer Lifespan: Moderate hardness causes significantly less wear on rotors compared to metallic pads, extending rotor life.

Drawbacks:

- Softer Initial Bite: When cold, ceramic pads have a slightly lower friction coefficient, leading to a "softer" initial pedal feel requiring deeper application for desired stopping power.

- Higher Cost: More expensive to produce than semi-metallic pads, often costing about twice as much.

- Reduced Low-Temp Performance: Braking performance can slightly diminish in cold winter or wet/snowy conditions, requiring earlier anticipation for stops.

- Best For: City commuters prioritizing cabin comfort and cleanliness, especially owners of electric sedans or family MPVs.

3. Semi-Metallic Brake Pads: The Durable "Performance" Option

Core Composition: Made primarily from metal fibers (steel wool, copper, iron powder), mixed with resins and friction modifiers. Metal content typically ranges from 30% to 60%.

Key Advantages:

Strong Braking Power: High friction coefficient provides fast response and strong initial bite, suitable for scenarios requiring urgent stops.

Wear Resistance & Durability: Hard metal materials wear slowly, often offering 20%-30% longer lifespan than OEM or ceramic pads, providing good value.

Stable Low-Temperature Performance: Effective in cold, damp environments, making them suitable for drivers in snowy northern winters.

Drawbacks:

- Noise & Dust Issues: Prone to generating harsh noise when metal contacts the rotor. The resulting black dust easily adheres to wheels, affecting appearance.

- Increased Rotor Wear: Harder metal fibers can accelerate rotor wear, potentially causing grooves over time and increasing future replacement costs.

- Average Heat Dissipation: Can experience noticeable brake fade during sustained, high-intensity braking, making them less ideal for prolonged mountain driving.

- Best For: Drivers frequently navigating mountain or mixed rural/urban roads, as well as off-road enthusiasts and manual transmission owners.

III. Buying & Replacement Tips – Must-Read to Avoid Pitfalls

Check Thickness, Replace Timely: Regularly inspect pad thickness. Replace immediately if worn below 3mm. If the wear indicator contacts the rotor, the pads are severely worn and require immediate replacement.

Choose Reputable Channels, Ensure Authenticity: Prioritize authorized auto parts stores or brand-authorized retailers to avoid counterfeit or refurbished pads. Verify anti-counterfeiting codes and certificates when purchasing.

Replace in Pairs for Balance: Always replace pads on both sides of an axle. Replacing only one side can cause uneven braking, leading to pulling or vibration.

Observe the Break-in Period, Avoid Hard Stops: After installation, gently drive for 200-300 miles to bed in new pads. Avoid hard or emergency braking during this period to allow proper mating with the rotors.

Consider Vehicle Type & Formula: Heavier vehicles (like many EVs) benefit from high-temperature resistant, stable-friction ceramic or OEM performance pads. Smaller economy cars can opt for cost-effective semi-metallic pads.

The market offers countless brake pads, but friction material formulas essentially fall into two categories: metallic and non-metallic (often called ceramic). What's the difference, and how should you choose?

Real User Insights:

Firstly, metallic formulas typically contain a high proportion of steel wool. The industry further subdivides these into low-metallic, semi-metallic, and full-metallic based on steel content. All metallic pads share the advantage of good heat dissipation from friction, making them suitable for heavier vehicles. A common drawback is that the harder material can more easily generate noise (squealing). Therefore, drivers sensitive to noise may not prefer metallic pads. There's no fixed rule assigning specific metallic formulas to certain vehicle types or brands; it often depends on regional usage habits or manufacturer specifications based on driver feedback.

Secondly, non-metallic formulas, as the name suggests, contain low levels of steel wool. Their pros and cons are generally the opposite of metallic formulas, making them better suited for drivers prioritizing braking comfort.

Observant owners might notice a thick layer of dust on their wheels while others' remain clean. This is also related to the pad formula. Some pads generate more dust during friction, which accumulates on wheels, while others produce less. This characteristic isn't absolutely tied to being metallic or non-metallic, as formulas can be adjusted to enhance or minimize specific properties.

In the aftermarket, there's no absolute "best" or "worst" brake pad. The most critical factor is safety and reliability. After all, brake pads are a safety component, and nothing is more important than safety.