FOR YOUR VEHICLE

DIY Brake Pad Replacement: Your Step-by-Step Guide & Safety Tips

Understanding Brake Pads & Replacement Needs

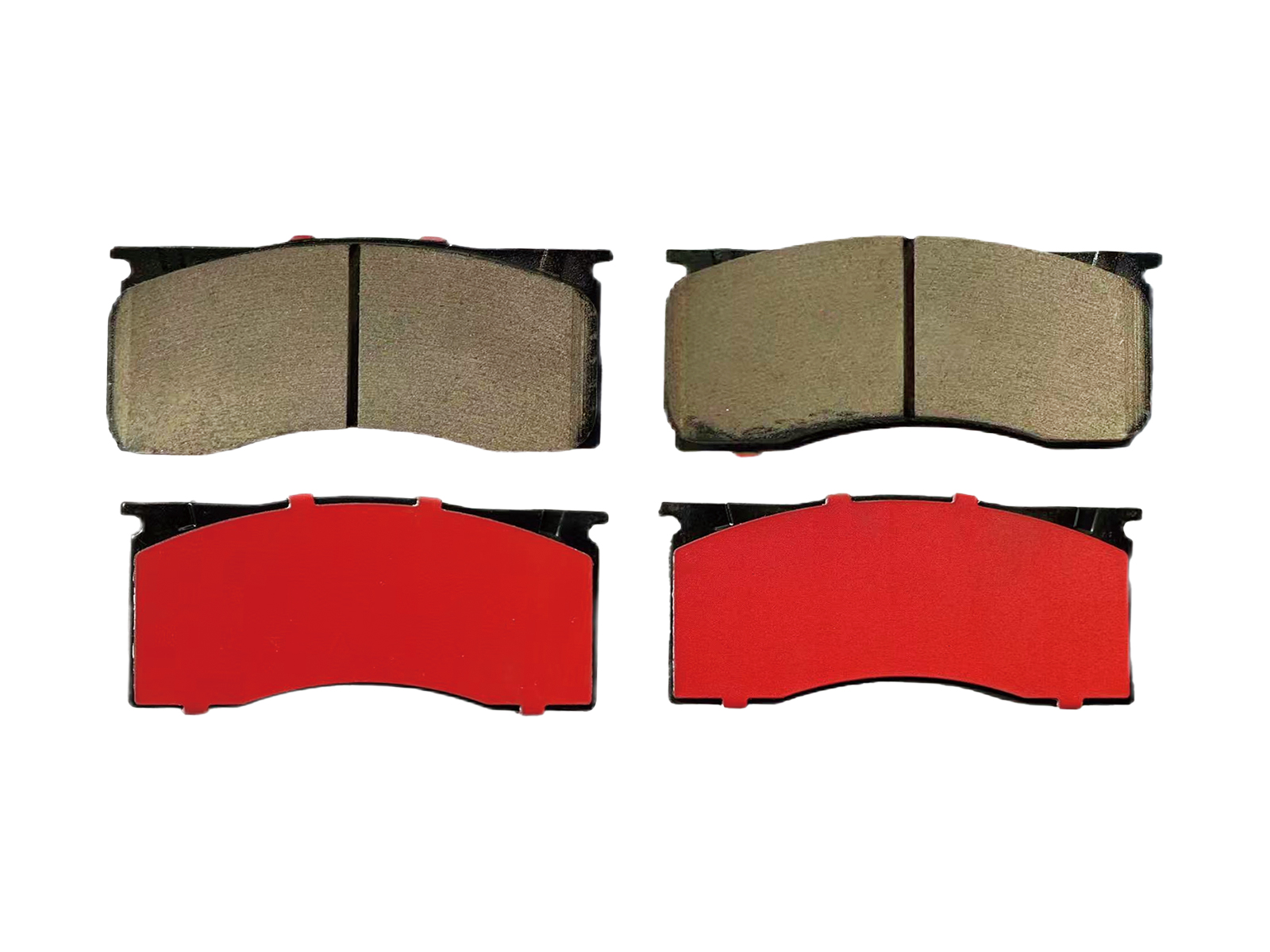

Brake pads are the core components of your vehicle's braking system, creating stopping power through friction with the rotors. Replace them when worn down to 3mm or less to maintain braking performance and ensure safety. Industry data from 2025 shows a 27% year-over-year increase in brake pad complaints, with 38% coming from first-time car owners. A common issue is shops recommending unnecessary replacements—like suggesting 6 or 8 pads when only the 4 front pads are needed—leading to hundreds in wasted spending.

Essential Tools & Preparation

Gather these tools before starting: a jack and jack stands, lug wrench, C-clamp, combination wrenches (typically 12-14mm), socket set, screwdriver, high-temperature brake lubricant (rated ≥300°C/572°F), new brake pads, and cleaning supplies. Most everyday vehicles (sedans, SUVs, minivans) use 4 front brake pads—2 per front wheel (inner and outer). Performance models with multi-piston calipers are the exception.

Park on a level surface and engage the parking brake. Loosen the lug nuts before lifting the vehicle. After raising the car with a quality jack, always secure it on jack stands—this is a critical safety step. Tighten stands to a recommended torque of ≥90 N·m (≈66 lb-ft). Before fully removing the tire, mark the wheel’s position relative to the hub for precise reinstallation.

Step-by-Step Replacement Procedure

First, remove the wheel completely. Before disassembling the caliper, check the brake fluid reservoir level—pushing the piston back may cause the fluid to rise. Use a C-clamp to slowly retract the caliper piston into its bore, creating necessary clearance for the thicker new pads.

Using the appropriate socket (usually 12-14mm), remove the caliper bolts. Carefully lift the caliper off the brake rotor and secure it with a wire or rope—never let it hang by the brake hose. Take out the worn brake pads from the caliper bracket.

This is the ideal time to inspect the brake rotor. If you find grooves deeper than 1.5mm or significant wear, consider replacing the rotor as well. Thoroughly clean the caliper bracket, then apply high-temperature brake lubricant to the contact points and slide pins.

Install the new brake pads, ensuring all shims or anti-noise clips are correctly seated. Carefully position the caliper over the new pads and rotor, then reinstall and torque the caliper bolts to specification.

Crucial Follow-Up Steps

After reassembly, pump the brake pedal 20-30 times until it feels firm—this restores the piston position and system pressure. Before driving, perform a low-speed brake test to verify proper operation.

On an initial road test, check for unusual noises or pulling. Note: new brake pads may produce slight noise during the break-in period (usually the first few hundred miles), which is normal. The break-in process also deposits a crucial transfer layer on the rotor surface.

Important Technical Considerations & Safety Warnings

When choosing replacement pads, consider material traits: semi-metallic pads cost less but may increase rotor wear, while ceramic pads offer quieter operation and less dust at a higher price. According to the GB 5763-2018 standard, quality brake pads should maintain a stable friction coefficient between 0.35 and 0.45.

Essential safety precautions include: never mix different pad materials on the same axle, as this can cause braking imbalance. After installation, eliminate excessive brake pedal travel—too much free play significantly increases stopping distance. Vehicles frequently driven in mountainous areas should have the brake system inspected every 30,000 miles, as long downhill grades accelerate wear.

Also, inspect related components including brake fluid moisture content (replace if over 3%) and brake hose condition. Professional inspections in 2025 revealed that 30% of repair shops exaggerated replacement needs or used inferior parts, especially targeting less-experienced owners. Understanding that a DIY front brake pad job typically costs $20-$50 in parts, while shops charge $80-$200 or more—and mastering the correct process—helps owners ensure top safety while avoiding unnecessary expenses.

Conclusion

With the right tools, careful preparation, and by following a systematic process, DIY brake pad replacement is an achievable task for most car owners. This comprehensive guide will help you significantly save on maintenance costs while keeping your braking system reliable. Remember, while the steps are straightforward, if you encounter any uncertainty or lack proper equipment, consulting a professional technician remains the safest choice for maintaining your vehicle's critical braking performance.