FOR YOUR VEHICLE

How to Choose Brake Pads: From Asbestos to Ceramic

From Asbestos to Ceramic: The History of Brake Pads & How to Choose

Tags: Ceramic Brake Pads, Metallic Brake Pads, Brake Pad Materials, Brake System Technology, Auto Safety Parts

When a mechanic suggests new brake pads, do terms like "ceramic," "semi-metallic," or "NAO" leave you confused? These names trace a mini-evolution of automotive safety technology. Each material shift—from harmful asbestos to today's high-performance ceramic composites—aims to stop your car more safely and reliably. Knowing this history cuts through the marketing hype and helps you make a truly informed decision.

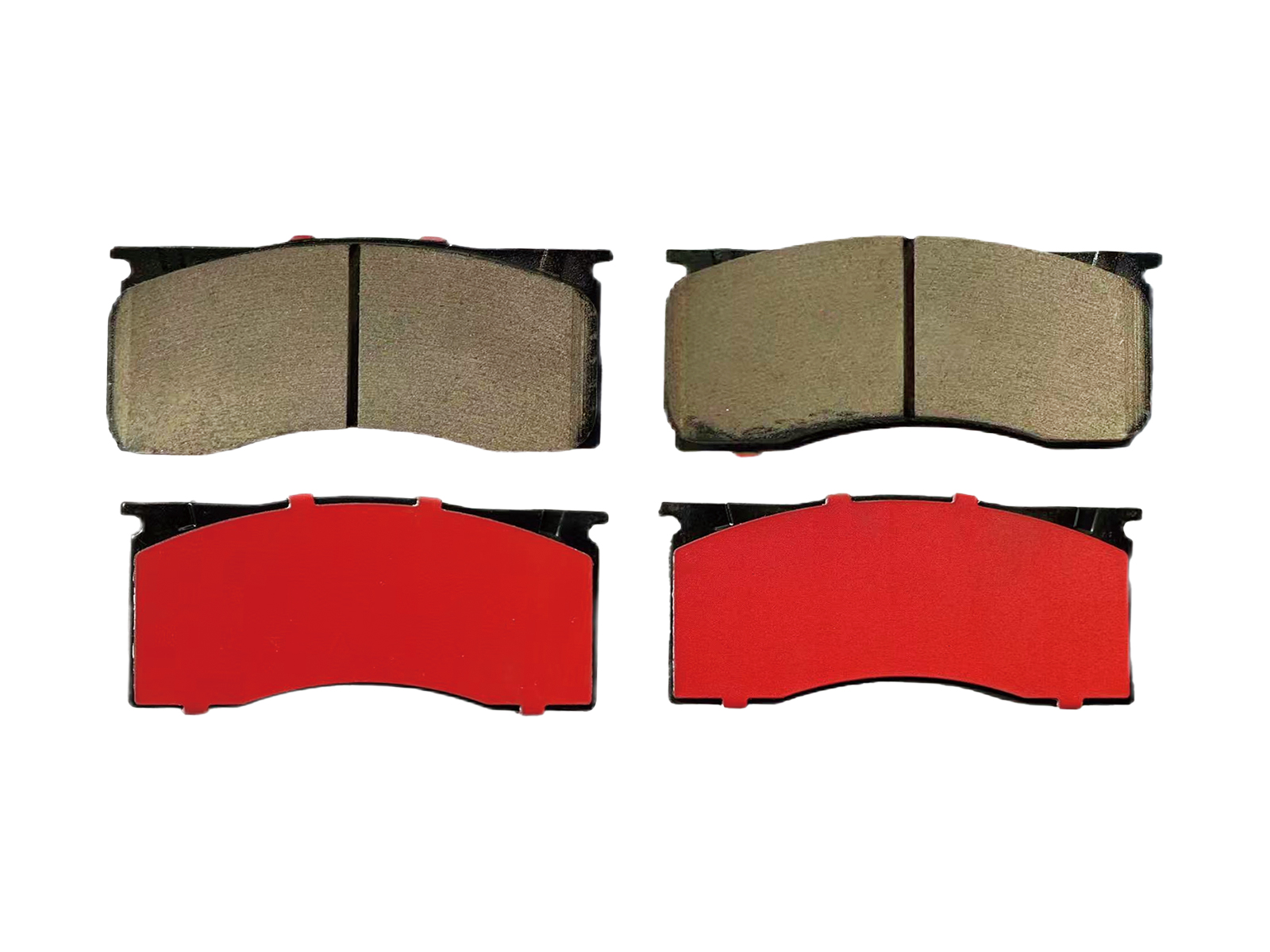

1. The Brake Pad: The Engineering Core of Stopping Power

Stopping a moving car safely relies on a precise hydraulic system. Pressing the pedal pushes fluid to the caliper, which squeezes the pads against a spinning rotor. This friction converts kinetic energy into heat.

The pad's friction material is the hero. It must work under extreme pressure and heat without wearing out or failing. Its quality dictates stopping power, noise levels, dust, and system longevity. Every material advance focuses on better performance, durability, and safety.

2. The Banned Beginning: Asbestos and the Rise of Organics

For most of the 20th century, asbestos was the standard for its heat resistance. But its fatal flaw emerged: inhaled asbestos dust causes severe lung disease and cancer. Health concerns led to a global ban.

NAO (Non-Asbestos Organic) pads replaced it. Made from glass/aramid fibers, rubber, and resin (sometimes with a little metal), they offer quiet operation and low dust. They were popular for comfort but can struggle under very high heat.

3. Performance & Compromise: The Era of Semi-Metallic Pads

For better heat resistance, semi-metallic pads became a top choice. Their material contains 30%–65% metal fibers (steel, copper, iron).

This brings key benefits: superior heat dissipation (preventing brake fade) and excellent performance under heavy use. They are also cost-effective.

The trade-offs are significant: more noise, abundant black dust that dirties wheels, and increased rotor wear. They are common on economy cars and in some performance applications.

4. The Modern Balance: Ceramic Brake Pads

Ceramic pads aim to balance organic comfort with metallic heat resistance. They are composites of ceramic fibers, aramid, minerals, and some copper—not brittle dinnerware.

They solve key issues: virtually no noise, minimal light-colored dust, and very gentle on rotors, with heat resistance rivaling semi-metallics.

The cost is high. Expensive materials and complex manufacturing (like sintering) make them pricier. In very cold weather, they may warm up slower. You pay a "tech premium" for all-around performance and cleanliness.

5. Making Your Choice: Match the Material to Your Driving

The best pad depends on your needs, not just the latest technology.

· Choose Semi-Metallic Pads if you drive aggressively, tow, or frequent mountains and need maximum heat resistance. You must accept more noise and dust.

· Choose Ceramic Pads if you commute daily, value a quiet, clean ride and long component life, and are willing to pay more upfront for these benefits.

· Choose Quality NAO Organic Pads if you drive gently, own an older car, or have a tight budget, and still want reliable stopping power.

Brake pad evolution reflects the auto industry's pursuit of safety, comfort, and eco-friendliness. Don't just buy for a label. Consider your driving style, environment, and budget. The right pad for your real-world use is the best safety investment. Always buy from reputable sources and have them installed by a professional.